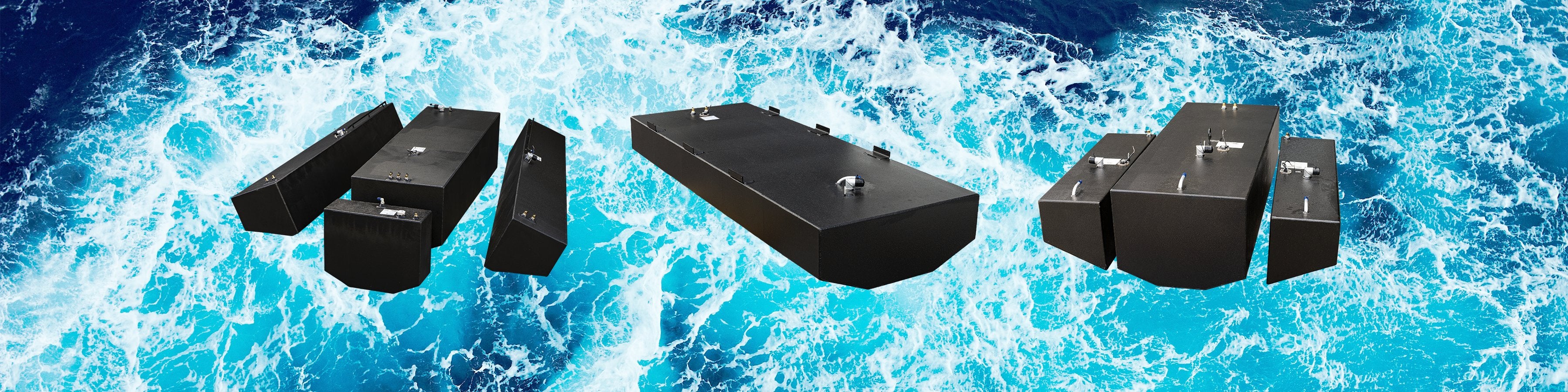

TANKS FAQ's

No. Typically, OEM part numbers for fuel tanks are solely for in-house record keeping so a third-party shouldn't be privy to the information that those numbers provide. So if we didn't make your boat's tank, no you can't.

A boat's Hull Identification Number (HIN), a.k.a boat VIN is little more useful in that it provides a little more information about the boat's make and year model, but often, tank specs can change between a given model's variants.

That, if you can find online a HIN decoder site that gives that info for free. So short answer, no. We can't use that info for knowing your tank's particular dimensions and fitting layout.

No. We've worked very hard and made a lot of very costly investments in machinery and personnel to afford our current, very fast (in comparison to the rest of the marine fuel tank industry), turnaround times. If you can't wait 2 weeks or less for your new tank please contact us to see if we have an urgent build slot available and be prepared to pay an extra premium for the rush job.

We're going to need you to provide us with your tank's dimensions and fittings layout, preferably in the form of a detailed drawing or sketch. If you don't have them, we know of 2 ways you can get those: contact your boat's manufacturer and ask for the tank's OEM drawings, or take the tank out of the hull, measure and draw it (follow the templates available here for guidance), and send those over via this email: info@weldingworldinc.com. You can typically get a build quote from us the same day you send it (if Mon.-Fri.), and the new tank on 2-weeks or less.

Keep in mind that we haven't built your tank yet, and that we will send you a complete set of detailed drawings of your tank via email ASAP upon receipt of your payment, and that we won't begin fabrication of your tank until we receive an email from you stating you're good with what you see, so you can make perfectly sure that what we will build fits what you need.

If you need to effect any minor changes to your tank's overall dimensions, and by 'minor' we mean a couple of inches more or less in any dimension, and any kind of changes to the fitting position or orientation on top of it, those will all be included in the price you pay. In some rare or extreme cases we could contact you with a build surcharge if the changes you need will make it cost more for us.

So up to your recent tank purchase nothing is written in stone and there's always space for negotiations, should you need them. That changes when you accept the tank's drawings, as from that point on we won't accept any changes and won't accept any tank returns. So make sure to check twice all measurements and fitting positions upon receipt of your new tank's drawings.

Short answer: of course, They're an indispensable structural device for aluminum tanks from a certain size on.

Welding World, Inc. is a long-standing member of the American Boat & Yacht Council (ABYC), which is an organization that develops voluntary global safety standards for the design, construction, maintenance, and repair of recreational boats and their components. The term 'voluntary', in the particular case of our marine fuel tank products, is kind of a misnomer because what originated as a voluntary industry standard became the Rule of the Land as the United States Coast Guard liked the ABYC fuel tanks standard so much they decided to make it part of the Code of Federal Regulations. So many of the design and manufacturing criteria applied to our products (as in installing baffles or not) isn’t a matter of choice for us, as it’s, literally, in the US law to have them correctly spec’d and installed.

On the other hand, we’re holders of several NMMA type certifications, specifically for our marine tanks, and that takes having a number of copies of our tanks sent to a certification lab to undergo a series of stringent, typically destructive testing, and all of those approvals validate our design and manufacture practices. The National Marine Manufacturers Association (NMMA) is another marine industry trade association that, among other things, maintains industry especific quality-assurance certification programs and for that works in close collaboration with the ABYC.

So, as required by law, our commitment as part of the trade associations we belong to, and ultimately, to further our own goal to always fullfil our customer’s quality and dependability expectations, you can have our guarantee that all possible provisions have been taken to assure you get the best built fuel, water, or waste tank from us.

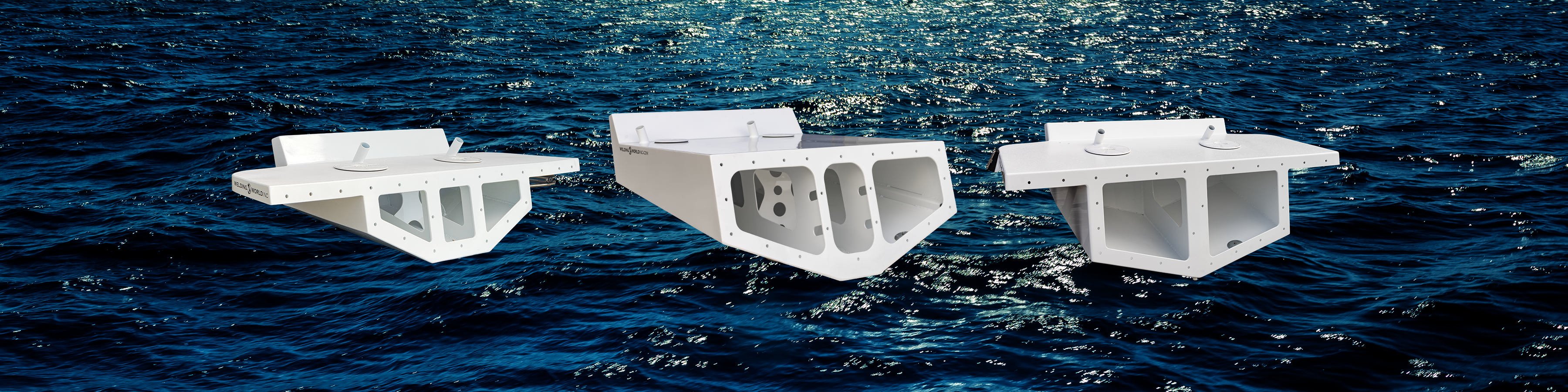

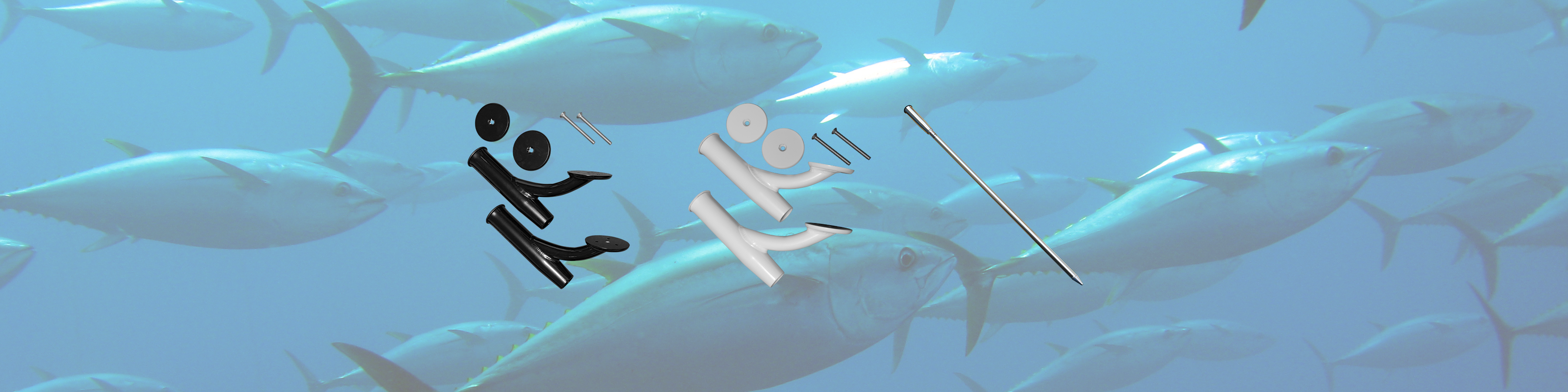

Brackets FAQ's

- Get your outboard's HP rating and shaft length. The outboard's shaft length will be essential to determine your bracket's mounting height, and your engine's power versus your hull's weight/load will allow for you to select the correct bracket setback distance. Typically, for a heavier/longer hull and low HP combination, a longer setback (e.g. 30" or more) is best. For a lightweight/short hull and higher power engine combination a shorter setback works better.

- Determine your bracket's setback distance.

- Determine your bracket's mounting height (see this video for single engine brackets, and this one for twins), which will allow you to select the right swim platform's width, and make sure your selected bracket's airbox height will allow for at least a 3.5" step to occur from the edge of your keel to the bottom of the bracket's airbox.

- Determine your swim platform's width.

- Measure your transom's vertical angle.

It mostly depends on your boat's transom height. Sometimes, your low profile transom wouldn't allow for any other type of bracket than a flat bottom one. Flat bottom bracket's are simple to make and typically take less material, so they are more economical.

With high flotation brackets you get a higher volume airbox and a wider, more distributed load-transference surface for your transom to carry. A higher volume airbox could help or completely compensate for the addition of the outboard's weight at the most leveraged position on your boat to give it a flatter at rest attitude or correct a previous bow high one. A high flotation bracket's geometry tends to be better at supporting high torsional/torque loads and the 'vee' bend in the bottom of their airboxes lends itself for better longitudinal load carrying.

This is a mainly esthetic decision, as the swim platform's width doesn't affect the performance of the bracket in any mayor way. We love gunwale to gunwale, full width swim platforms, as we personally feel they tend to tie together the back of most boats just right, but that's us. A wider swim platform affords a bigger stage on which to fight and load in a feisty big catch, or more space to check on an outboard from the deck, or to lay tools/spares when doing maintenance on the engines ashore. The wider the platform, the costlier the bracket though, as that's one of the major cost driving choices.